Components

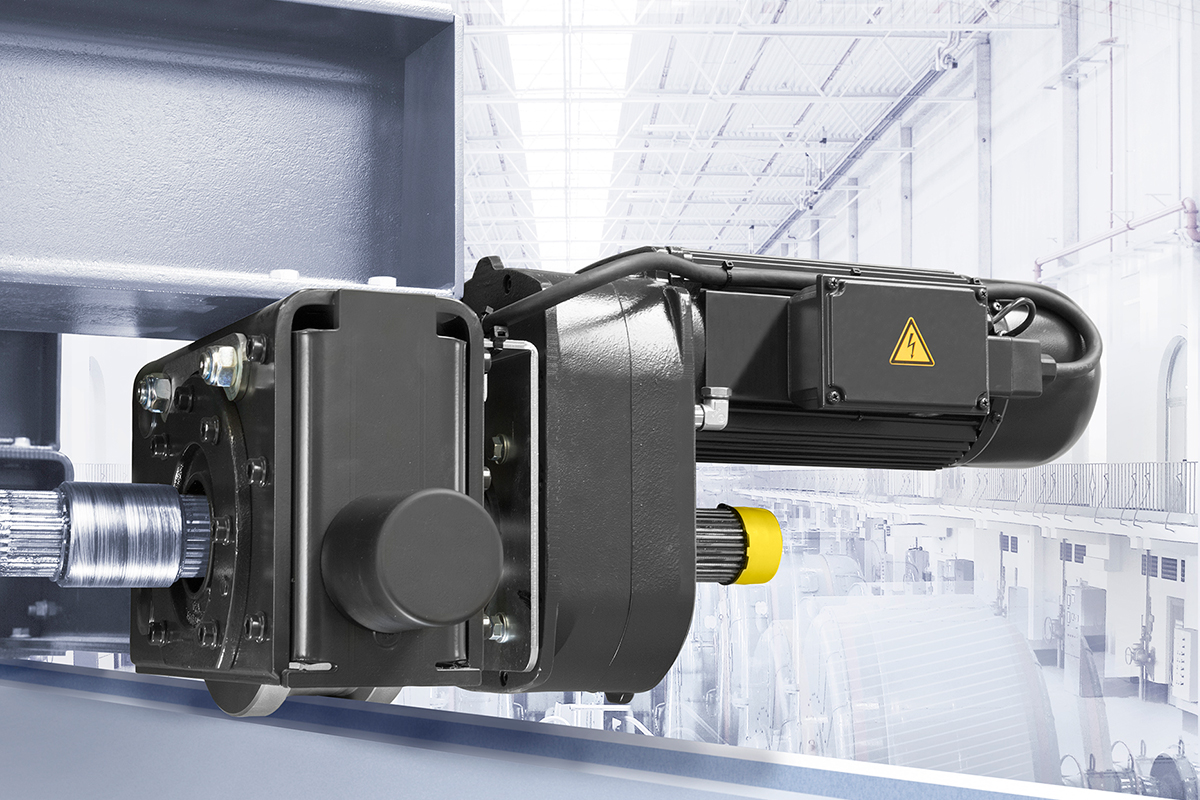

Travel drives

System benefits:

- Choose from 2 standard drives:

5/20 m/min or 10/40 m/min - Stepless speed control with even smoother running characteristics

(on request) - Power reserves thanks to high duty cycle: 60 % DC

- Maintenance-free gear with lifetime lubrication

- Smooth running characteristics thanks to integrated centrifugal mass and low-noise gears

- Safe power transmission by spline shaft to DIN 5480

- Comprehensive equipment: integrated disc brake, integrated torque support

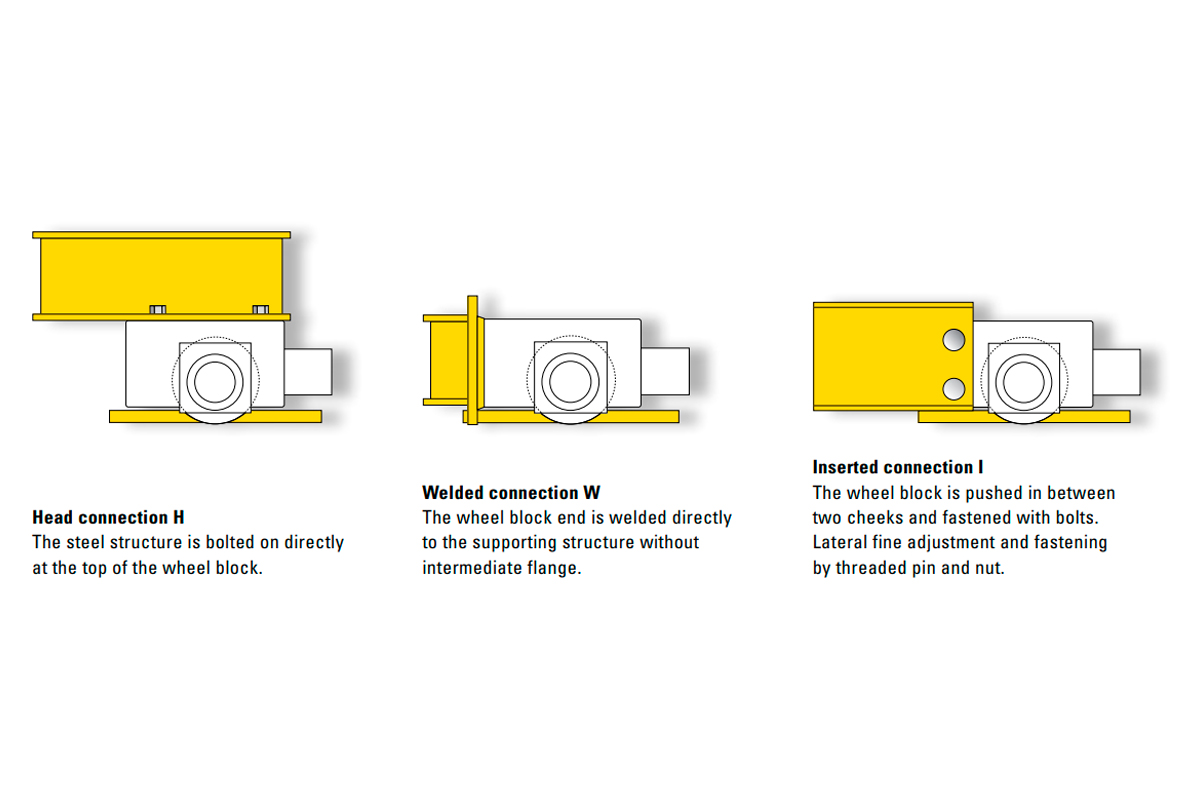

SR wheel block system

System benefits:

- Universal use for wheel loads from 5 t to 30 t in 6 frame sizes

- 5 standard configurations provide maximum flexibility for connecting to customers' structural steelwork

- Reliable drives for every requirement

- Wheel in spheroidal graphite cast iron EN-GJS-700 (GGG70), with flanges on both sides for quiet running and reducing wear on the runway

- Self-lubrication ensures minimum wear

- Lifetime lubrication of roller bearings

- Maintenance-friendly as wheel can simply be pulled out to the front

- Up-to-date manufacturing technology with lasered sheet steel parts

- Inherently stable housing enclosed on

5 sides - Generously dimensioned ground clearance

- Space-saving pancake gear

(on request) - SFD frequency inverter

Crane endcarriages

System benefits:

- Compact and robust

- Manufacture in up to date series production

- Wheels in high-quality self-lubricating spheroidal graphite cast iron

- Low-noise wheel drive

- Smooth starting and braking characteristics for safe operation and long service life

- Simple adjustment to crane runway profile

- Minimum stress on crane runway girder

- Maintenance-friendly

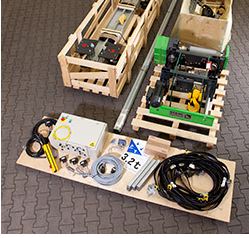

CraneKits for crane manufacturers

System benefits:

- All components are tested before delivery

- Plug and play: pre-assembled cables

- All connections are clearly labelled

- Cable trolleys are pre-assembled

- Convenient planning and ordering using the CraneGuide software

- Engineering support from

STAHL CraneSystems’ experts - Factory service centre helps with tricky problems

- No competition: STAHL CraneSystems is a crane technology specialist and does not build crane systems itself.

- Sole supplier of explosion-protected CraneKits

Control technology

System benefits:

- All electrical devices are wired onto a terminal strip in the hoist panel box

- All common control voltages available

- Plug connection of all important components

- Crane manufacturers can easily connect their own controls.

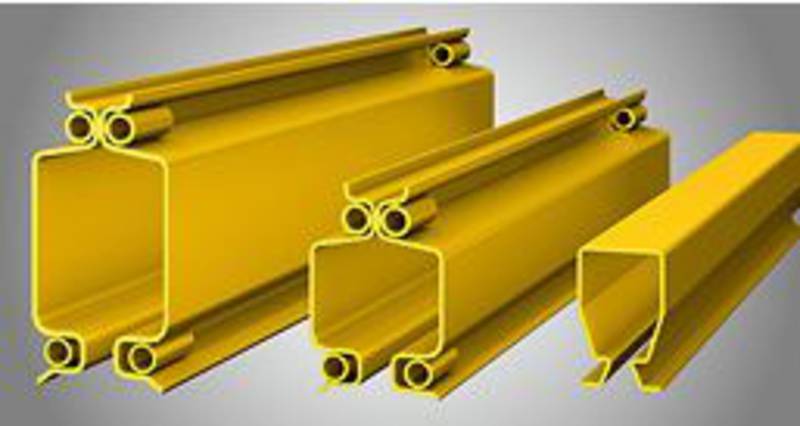

KS light crane technology

System benefits:

- Closed UKA profiles of quality high-tensile steel RSt-37-2 with powder coating

- Modular design, easy to erect

- 3 frame sizes for load capacities from 125 kg to 2,000 kg

- Combination of different profiles is possible

- Monorail runways, single or double girder overhead travelling cranes

- Cranes in raised design

- Floating suspension

- Suspensions with universal joints reduce the horizontal forces acting on the structural steelwork

- Suspension in various designs and widths

- Bolt connections, no welding necessary

- Wide spans

- Push trolleys for smooth travel

- Low wear and abrasion thanks to state-of-the-art nylon wheels

- No limiting of max. distance between suspension and joint necessary up to 1,000 S.W.L.

KA light crane technology

System benefits:

- Closed, aluminium profiles, corrosion-resistant and anodised, long-lived

- High bending strength

- Low weight, low roll resistance (both reduced by approx. 50 % compared with KS light crane technology)

- Modular construction, simple erection

- 4 frame sizes for S.W.L.s from 125 kg to 2,000 kg

- Monorail runways, single or double girder overhead travelling cranes

- Cranes in raised design

- Floating suspension

- Precise rail joints

- Push trolleys for smooth travel

- Low wear and abrasion thanks to state-of-the-art nylon wheels

- Extremely smooth, frictionless, fast travel

- Wide spans